Factors Affecting Epoxy Flooring Cost

When it comes to installing epoxy flooring, understanding the factors that influence the overall cost is crucial for making informed decisions. Whether you're a homeowner in Kansas City looking to enhance your garage, a real estate investor aiming to increase property value, or a business owner seeking durable flooring solutions, knowing what drives the cost can help you plan your budget effectively. This comprehensive guide will delve into the various elements that impact the cost of epoxy flooring, from material types and installation methods to surface preparation and geographical location.

Epoxy flooring is prized for its durability, aesthetic appeal, and versatility. However, the cost can vary widely depending on several factors. This blog aims to provide a detailed breakdown of these factors, helping you make the best choice for your specific needs and budget.

Material Costs

The type of epoxy material you choose is a significant factor in determining the overall cost of your flooring project. There are three main types of epoxy used in flooring applications:

Water-Based Epoxy

This is generally the most affordable option. It is easy to apply and has lower VOC levels, making it more environmentally friendly. However, it is less durable than other types and may not be suitable for high-traffic areas.

Water-based epoxy is often used in residential settings where heavy-duty performance is not required. Homeowners in Kansas City, Lenexa, and Olathe who are looking for an eco-friendly and cost-effective option for their garage or basement might find water-based epoxy to be a suitable choice. The cost for water-based epoxy can range from $0.50 to $2.00 per square foot, depending on the brand and quality. This type of epoxy is also ideal for DIY enthusiasts who want a straightforward application process.

Solvent-Based Epoxy

This type of epoxy is more durable and resistant to chemicals and abrasion. It offers a glossy finish and better adhesion but comes with higher VOC levels, requiring proper ventilation during application. The cost is higher than water-based epoxy but provides better longevity.

Solvent-based epoxy is ideal for commercial and industrial settings in Kansas City and Overland Park where durability and chemical resistance are crucial. Businesses that deal with chemicals, such as automotive workshops or manufacturing plants, often prefer solvent-based epoxy. The cost for solvent-based epoxy typically ranges from $1.50 to $4.00 per square foot. This type of epoxy requires professional application due to the fumes and complexity of the process, ensuring a high-quality finish that stands up to demanding environments.

100% Solid Epoxy

Known for its superior durability and strength, 100% solid epoxy is the most expensive option. It is highly resistant to chemicals, stains, and heavy traffic, making it ideal for industrial and commercial applications. The absence of solvents means there are no VOC emissions, but the installation process is more complex.

For clients in Kansas City seeking the highest quality and performance, 100% solid epoxy is the top choice. It is perfect for high-traffic areas like warehouses, hospitals, and commercial kitchens. The cost for 100% solid epoxy can range from $3.00 to $7.00 per square foot, reflecting its premium quality and performance. This type of epoxy is often used in environments that require maximum durability and a flawless finish.

Labor Costs

Labor costs can vary significantly depending on whether you opt for professional installation or decide to go the DIY route. Here’s what you need to consider:

Professional Installation

Hiring professionals ensures that the epoxy is applied correctly and efficiently. The cost includes surface preparation, material mixing, application, and finishing. Professional installers bring expertise and specialized equipment, which can result in a more durable and aesthetically pleasing finish. Labor costs can range from $3 to $12 per square foot, depending on the complexity of the job and the experience of the installer.

In Kansas City, finding reputable epoxy flooring professionals is crucial for achieving the best results. Local contractors familiar with the area’s specific conditions and requirements can provide tailored solutions. The cost of professional installation may vary depending on local labor rates and the complexity of the project. For instance, businesses in Lenexa and Olathe might find that labor rates are slightly lower than in downtown Kansas City due to differing living costs and market conditions.

DIY Installation

While doing it yourself can save on labor costs, it requires a good understanding of the materials and process. DIY kits are available and typically cost less than hiring professionals, but the results may not be as durable or aesthetically perfect. Additionally, mistakes in the application can lead to higher costs for repairs.

Homeowners in Kansas City who are handy and have experience with DIY projects might consider this option to save money. However, it’s essential to weigh the potential risks and ensure you have the necessary skills and tools to achieve a satisfactory result. DIY epoxy kits can range from $1 to $5 per square foot, depending on the quality of the kit and the complexity of the project.

Surface Preparation

Proper surface preparation is crucial for the success of an epoxy flooring installation and can significantly impact the overall cost. Preparation steps may include:

Cleaning

The surface must be free of dust, dirt, grease, and other contaminants. Professional cleaning can add to the cost, but it ensures a better bond between the epoxy and the substrate. In Kansas City, local cleaning services can provide this essential step, ensuring the surface is adequately prepared for epoxy application. The cost of professional cleaning can range from $0.50 to $1.50 per square foot.

Repairs

Any cracks, holes, or uneven areas in the concrete need to be repaired before applying the epoxy. The cost of repairs depends on the extent of the damage. For homeowners and businesses in Lenexa and Olathe, addressing these issues beforehand can prevent future problems and enhance the longevity of the epoxy floor. Concrete repair costs can range from $2 to $4 per square foot, depending on the severity of the damage.

Priming

Applying a primer coat can enhance the adhesion and longevity of the epoxy floor. Primers can also seal the concrete, preventing moisture from affecting the epoxy. The cost of priming varies but is a worthwhile investment for a durable floor. In Kansas City, local suppliers offer a range of primers suited to different types of epoxy and concrete conditions. Primer application typically costs between $1 and $2 per square foot.

Square Footage

The size of the area to be covered with epoxy flooring is a direct cost factor. Larger areas require more materials and labor, which increases the total cost. Here’s how square footage impacts pricing:

Economies of Scale

While larger projects will cost more in total, the cost per square foot may decrease as the area increases due to economies of scale in material purchase and labor efficiency. For large commercial spaces in Overland Park, this can result in significant savings per square foot. For example, a 10,000-square-foot warehouse might see costs as low as $5 per square foot compared to $10 per square foot for a smaller 500-square-foot garage.

Small Spaces

Smaller areas might have a higher cost per square foot because of the fixed costs associated with setup and preparation, regardless of the total area size. For homeowners in Kansas City looking to epoxy a small garage or basement, it’s important to consider these fixed costs when budgeting. Even small spaces will incur costs for material preparation, which can make the overall cost per square foot appear higher. For instance, a 200-square-foot space might cost $1,000, translating to $5 per square foot.

Additional Features

Customizations and additional features can enhance the appearance and functionality of your epoxy floor but will also add to the cost. These features include:

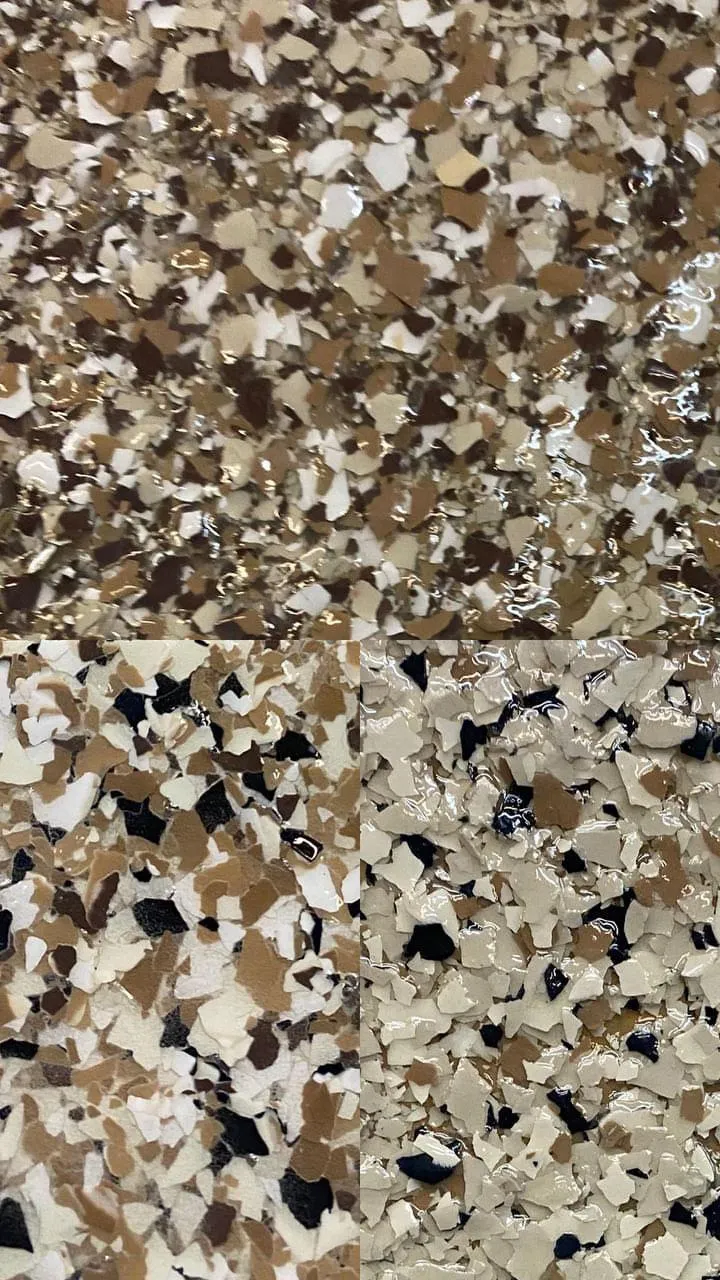

Decorative Flakes

Adding decorative flakes or chips can create a unique and attractive finish. The cost depends on the type and amount of flakes used. In Kansas City, local suppliers offer a variety of decorative options to match your aesthetic preferences. The cost for decorative flakes typically ranges from $0.25 to $1 per square foot, depending on the complexity of the design and the quantity of flakes used.

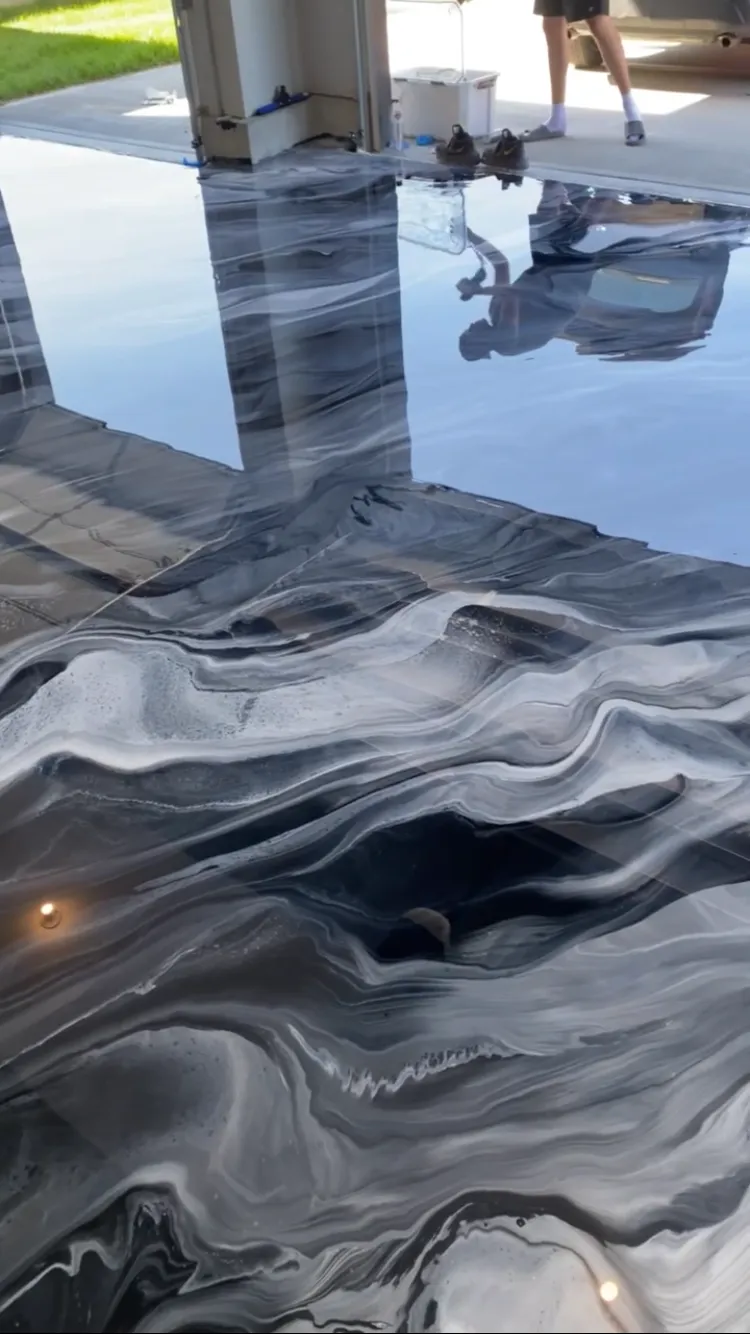

Color Choices

Custom color blends and special pigments can increase the price. High-grade metallic or marble finishes are particularly costly but offer stunning visual appeal. For businesses in Lenexa and Olathe looking to make a statement with their flooring, investing in custom colors can create a memorable impression. Custom color options can add $1 to $3 per square foot to the overall cost.

Topcoats and Finishes

Additional topcoats can enhance the durability and shine of the epoxy floor. Options like anti-slip additives, UV protectants, or high-gloss finishes add to the cost but provide functional and aesthetic benefits. Local suppliers in Overland Park offer a range of topcoat options to meet your specific needs. Topcoat application costs can range from $1 to $2 per square foot, depending on the type of finish desired.

Logos and Graphics

For commercial spaces, adding logos or custom graphics can create a professional and branded look. This is particularly useful for showrooms, offices, and retail environments. The cost of adding logos and graphics varies based on the complexity of the design and the size of the area. Custom logos and graphics can add $2 to $5 per square foot.

Geographical Location

The location of your project can influence the cost due to variations in labor rates and material availability. Consider the following:

Labor Rates

Labor costs can vary widely depending on the region. Urban areas with higher living costs generally have higher labor rates compared to rural areas. In Kansas City, it’s essential to get multiple quotes from local contractors to find the best balance between cost and quality. For example, labor rates in downtown Kansas City might be higher than in Lenexa or Olathe due to the higher cost of living and demand for services.

Material Costs

The cost of materials may also vary based on location due to shipping costs, local demand, and availability. Proximity to suppliers and manufacturers can affect pricing. In Kansas City, working with local suppliers can reduce shipping costs and support the local economy. Material costs might be lower in areas close to major supply hubs compared to more remote locations.

Local Regulations

Some areas may have stricter regulations regarding VOC emissions and disposal of materials, potentially increasing the cost of the project. Ensuring compliance with local regulations in Lenexa and Olathe is essential to avoid fines and ensure the safety and legality of your project. Adhering to these regulations might require the use of specific low-VOC materials or additional safety measures, which can increase costs by $0.50 to $1 per square foot.

Conclusion

Understanding the factors that affect the cost of epoxy flooring can help you make informed decisions and effectively plan your budget. From choosing the right materials and labor options to considering surface preparation and additional features, each element plays a crucial role in determining the overall expense. At Onyx Luxury Epoxy, we are committed to providing high-quality, durable epoxy flooring solutions tailored to meet your specific needs and budget. Whether you are enhancing a residential space, upgrading a commercial property, or seeking a robust industrial flooring solution, our team of experts is here to guide you through every step of the process.

Investing in epoxy flooring is a decision that offers long-term benefits in durability, aesthetics, and value. Contact Onyx Luxury Epoxy today to learn more about our services and how we can help you achieve the perfect flooring solution for your space.

Key Takeaways

Material Choices Matter: The type of epoxy material you choose—water-based, solvent-based, or 100% solid—will significantly impact your cost. Each has its own advantages and price points.

Professional vs. DIY: While DIY can save on labor costs, professional installation ensures a high-quality finish and durability, especially for large or complex projects.

Surface Preparation is Crucial: Proper cleaning, repairs, and priming are essential for a successful epoxy floor installation and can add to the overall cost.

Square Footage Considerations: Larger areas benefit from economies of scale, reducing the cost per square foot, while smaller areas may have higher per-square-foot costs due to fixed preparation costs.

Customization Costs: Additional features like decorative flakes, custom colors, and topcoats can enhance the look and functionality of your floor but will increase the overall cost.

Location Influences Cost: Geographical location affects labor rates, material costs, and regulatory requirements, impacting the total cost of your epoxy flooring project.