Guide to Self-Leveling Epoxy Floors

Today, I want to talk to you about one of the most versatile and visually appealing flooring options available: self-leveling epoxy floors. Whether you're renovating your home in Overland Park or upgrading your commercial space in Kansas City, self-leveling epoxy flooring can provide a seamless, durable, and aesthetically pleasing solution. Let's dive into everything you need to know about this innovative flooring option.

What Are Self-Leveling Epoxy Floors?

Self-leveling epoxy floors are a type of epoxy coating that is applied over concrete floors to create a smooth, seamless surface. As the name suggests, this type of epoxy is self-leveling, meaning it flows and settles into a flat, even layer across the floor. This creates a flawless finish that is not only attractive but also highly durable.

How Are Self-Leveling Epoxy Floors Installed?

Installing self-leveling epoxy floors requires precision and expertise to ensure a flawless finish. Here’s a step-by-step guide to the installation process:

1. Surface Preparation

The first step in installing self-leveling epoxy floors is preparing the surface. This involves cleaning the concrete substrate thoroughly to remove any dirt, grease, or oil. Any existing coatings or sealants must also be removed. The surface is then inspected for cracks and imperfections, which are repaired to create a smooth base for the epoxy.

2. Primer Application

Once the surface is prepared, a primer is applied. The primer helps the epoxy adhere better to the concrete and seals the substrate to prevent air bubbles from forming in the epoxy layer. It is essential to allow the primer to cure fully before proceeding to the next step.

3. Mixing the Epoxy

The self-leveling epoxy is then mixed according to the manufacturer’s instructions. This typically involves combining the resin and hardener components. Proper mixing is crucial to ensure the epoxy cures correctly and achieves the desired properties.

4. Pouring and Spreading the Epoxy

The mixed epoxy is poured onto the prepared surface and spread evenly using a notched squeegee or trowel. The epoxy will flow and level itself out, creating a smooth, even layer. It is important to work quickly and efficiently, as the epoxy begins to cure once mixed.

5. Finishing Touches

After the epoxy is spread, any desired finishes or textures can be added. This might include adding decorative flakes or creating a textured surface for slip resistance. The floor is then left to cure completely, which can take several days depending on the specific epoxy used and environmental conditions.

What Are the Benefits of Self-Leveling Epoxy Floors?

Self-leveling epoxy floors offer numerous benefits, making them a popular choice for both residential and commercial applications. Here are some of the key advantages:

1. Seamless and Smooth Finish

One of the most significant benefits of self-leveling epoxy floors is their seamless and smooth finish. This not only enhances the aesthetic appeal of the floor but also makes it easy to clean and maintain. The absence of seams and joints prevents dirt and bacteria from accumulating, making it an excellent choice for environments that require high standards of hygiene.

2. Durability and Longevity

Self-leveling epoxy floors are known for their durability. They can withstand heavy foot traffic, machinery, and even vehicles, making them ideal for garages, warehouses, and industrial spaces. Additionally, these floors are resistant to chemicals, oil, and water, ensuring they maintain their appearance and functionality for years to come.

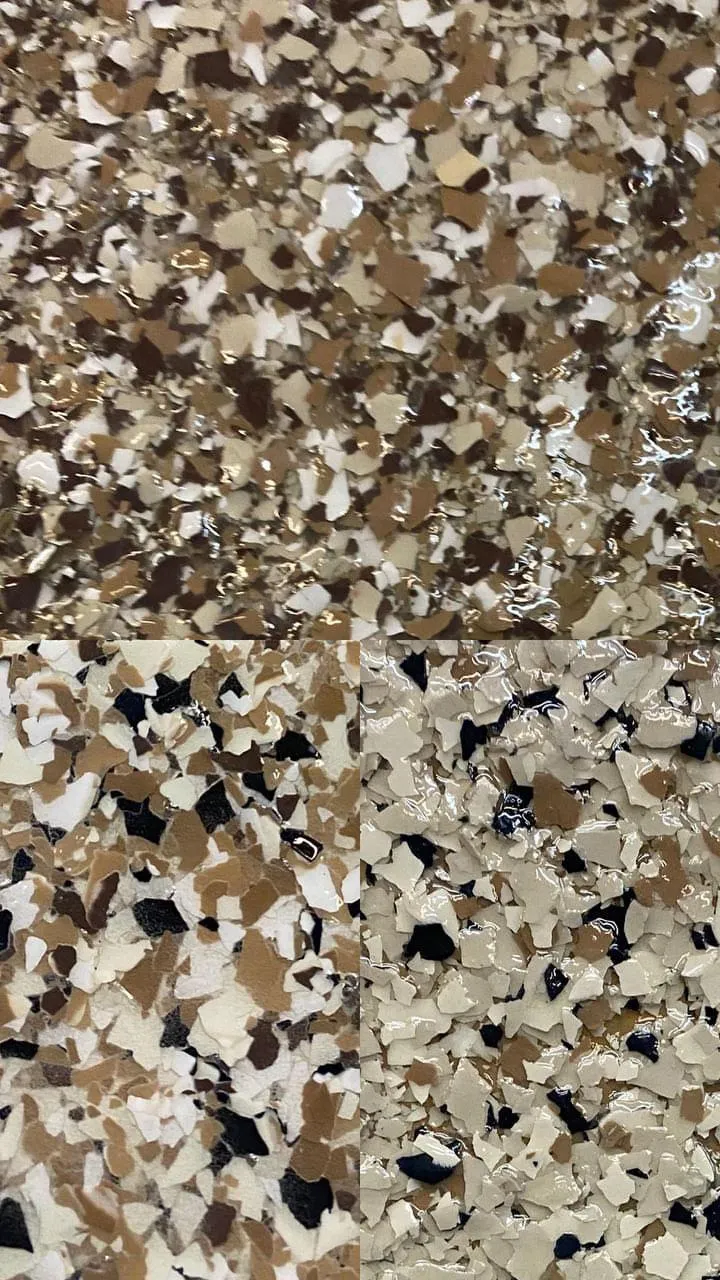

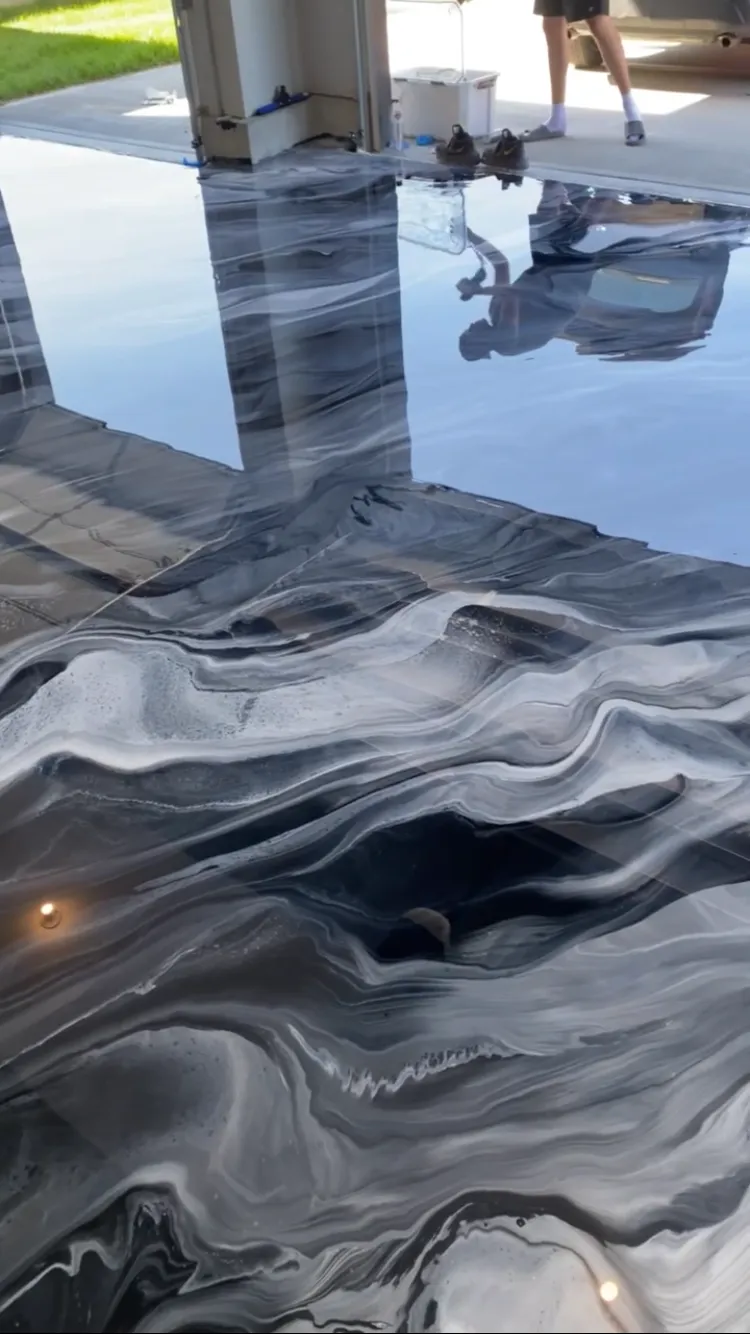

3. Aesthetic Appeal

Available in a wide range of colors and finishes, self-leveling epoxy floors can be customized to fit any design aesthetic. Whether you prefer a high-gloss finish for a modern look or a matte finish for a more subtle appearance, there is an option to suit your style. Metallic and decorative flake finishes can also add a unique touch to your space.

4. Easy Maintenance

Maintaining self-leveling epoxy floors is straightforward. Regular sweeping and occasional mopping with a mild detergent are usually sufficient to keep the floors looking new. Their resistance to stains and spills also makes them an excellent choice for areas prone to messes, such as kitchens and workshops.

5. Safety Features

Epoxy floors can be made slip-resistant by adding aggregates or textured finishes, enhancing safety in areas where spills and moisture are common. This makes them suitable for commercial kitchens, bathrooms, and other environments where slip hazards are a concern.

Applications of Self-Leveling Epoxy Floors

Self-leveling epoxy floors are incredibly versatile and can be used in various settings. Here are some common applications:

1. Residential Spaces

In homes, self-leveling epoxy floors are often used in garages, basements, kitchens, and living areas. Their seamless finish and wide range of design options make them an attractive choice for homeowners looking to upgrade their flooring.

2. Commercial Spaces

Commercial spaces such as retail stores, offices, and showrooms benefit from the durability and aesthetic appeal of self-leveling epoxy floors. They provide a professional look while withstanding the wear and tear of heavy foot traffic.

3. Industrial Settings

In industrial settings like warehouses, factories, and workshops, self-leveling epoxy floors offer the durability needed to handle heavy machinery and equipment. Their resistance to chemicals and spills also makes them suitable for environments where such hazards are present.

4. Healthcare Facilities

Healthcare facilities require flooring that is easy to clean and maintain. The seamless nature of self-leveling epoxy floors prevents the accumulation of dirt and bacteria, making them an ideal choice for hospitals, clinics, and laboratories.

Tips for Maintaining Self-Leveling Epoxy Floors

To keep your self-leveling epoxy floors in top condition, follow these maintenance tips:

1. Regular Cleaning

Sweep or vacuum your floors regularly to remove dust and debris. For a deeper clean, mop the floors with a mild detergent and warm water. Avoid using harsh chemicals that can damage the epoxy surface.

2. Protect from Heavy Impacts

While epoxy floors are durable, they can still be damaged by heavy impacts. Use protective pads under heavy furniture and equipment to prevent dents and scratches.

3. Address Spills Promptly

Clean up spills as soon as they occur to prevent staining and damage. Epoxy floors are resistant to most chemicals, but prompt cleaning ensures they remain in pristine condition.

4. Inspect Regularly

Periodically inspect your floors for any signs of wear or damage. Addressing minor issues early can prevent them from becoming more significant problems, extending the life of your epoxy flooring.

Conclusion

Self-leveling epoxy floors offer a versatile, durable, and aesthetically pleasing solution for a wide range of applications. Whether you're upgrading your home, commercial space, or industrial facility, these floors provide a seamless, easy-to-maintain surface that stands the test of time.

At Onyx Luxury Epoxy, we specialize in installing high-quality self-leveling epoxy floors that meet the unique needs of our clients in Kansas City, Overland Park, and beyond. Our team of experts is here to guide you through the process and ensure you achieve the perfect finish for your space.

Call to Action: Ready to transform your floors with self-leveling epoxy? Contact Onyx Luxury Epoxy today to schedule your free consultation. Visit Onyx Luxury Epoxy to request your free quote and take the first step towards beautiful, durable flooring.

Thank you for considering Onyx Luxury Epoxy for your flooring projects. We look forward to helping you achieve the perfect floors for your space.