Polyaspartic Coatings: The High-Performance Flooring Choice Built for Extreme Durability and Fast Results

Imagine walking into a garage or commercial space where the floor shines as if it were brand new, yet it’s been through years of heavy use. That’s the magic of polyaspartic coatings! With durability so high that they can withstand everything from forklift traffic to oil spills, and a curing time that’s lightning-fast, these coatings are changing the game in flooring solutions. Polyaspartic coatings cure in as little as an hour—compare that to the days it takes epoxy to set. This isn't just a cosmetic upgrade; it’s a high-performance solution designed to last.

But let’s break it down. If you're a property manager, business owner, or homeowner looking to invest in a floor that endures, resists wear, and still looks impressive, polyaspartic coatings could be exactly what you’re after. In this guide, we’ll dive into what makes these coatings unique, when to choose them over epoxy, and the real-world benefits they bring. Stick around—this is the ultimate guide to polyaspartic coatings, where form meets function, and speed doesn’t sacrifice strength.

What Are Polyaspartic Coatings?

Imagine a coating that’s tough enough for industrial spaces but refined enough for high-end residential use. That’s exactly what polyaspartic coatings deliver. Developed from advanced polyurea chemistry, these coatings bring a new level of resilience to floors. Originally designed to withstand the wear and tear of warehouses and manufacturing floors, polyaspartics are now elevating spaces everywhere—garages, kitchens, and even showrooms.

What sets polyaspartic coatings apart? Speed and strength. They cure in as little as an hour, creating a seamless protective layer that’s almost immediately ready for action. And it’s not just about fast drying. Polyaspartic coatings are engineered to resist chemicals, abrasions, and UV rays, making them incredibly durable across a wide range of conditions. Unlike traditional epoxy, which can take days to cure, polyaspartics offer a near-instant solution for spaces that need to get back to business without delay.

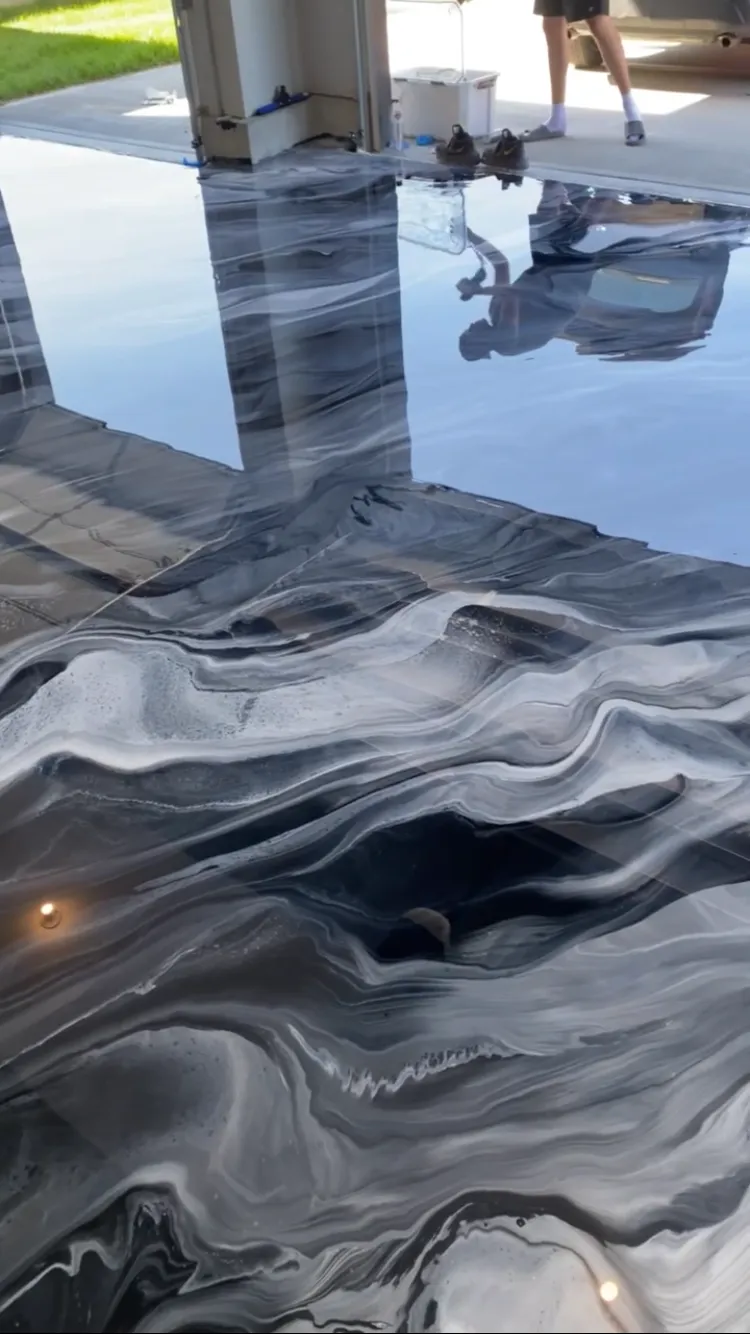

The versatility here is remarkable. Not only are polyaspartic coatings strong, but they’re also flexible enough to be customized with colors, textures, and designs to suit any aesthetic vision. Whether it’s a sleek, polished floor for a modern kitchen or a rugged, stain-resistant surface for a garage, polyaspartics adapt beautifully. These coatings bring both beauty and brawn, proving that functional doesn’t have to mean dull.

For property managers, business owners, or homeowners, this coating offers a powerful upgrade. Polyaspartics are designed to endure heavy traffic and tough conditions while looking impressive year after year. The combination of durability and style makes them a standout choice for anyone looking to invest in a high-performance floor solution.

Benefits of Polyaspartic Coatings

Polyaspartic coatings don’t just look good—they perform at a whole new level. These coatings offer a unique blend of speed, durability, and aesthetic flexibility that make them a favorite for both residential and commercial spaces. Here’s a closer look at what makes polyaspartic coatings a standout choice:

1. Rapid Curing Times

Need a fast turnaround? Polyaspartic coatings cure in just a few hours, allowing spaces to be back in action the same day. This rapid curing is a game-changer, especially for businesses that can't afford lengthy downtimes. Imagine finishing a high-traffic area in the morning and having it ready for customers by afternoon—that’s the efficiency polyaspartics deliver. Quick, but without compromising on strength.

2. UV Resistance

Sunlight can be brutal on floors, causing many coatings to yellow or fade over time. Not with polyaspartic. These coatings stay clear and vibrant, even in direct sunlight or brightly lit rooms. It’s a perfect choice for outdoor patios, showrooms with large windows, or any space where UV exposure is a concern. The benefit? Long-lasting color and clarity, with no cracking or discoloration over time.

3. High Durability and Chemical Resistance

Whether it’s an industrial workshop, a garage, or a commercial kitchen, floors face constant abuse from spills, oils, salts, and heavy traffic. Polyaspartic coatings are designed to withstand it all. They’re highly resistant to abrasions and chemicals, making them ideal for settings where durability is non-negotiable. Floors coated with polyaspartic stay intact and look good, even in the most demanding environments.

4. Temperature Flexibility

From refrigerated storage rooms to sun-soaked patios, polyaspartic coatings handle temperature extremes with ease. They can be applied at temperatures ranging from -22°F to 140°F, making them incredibly versatile. Whether you’re in a cold climate or a desert heatwave, polyaspartic remains stable, durable, and safe for use year-round.

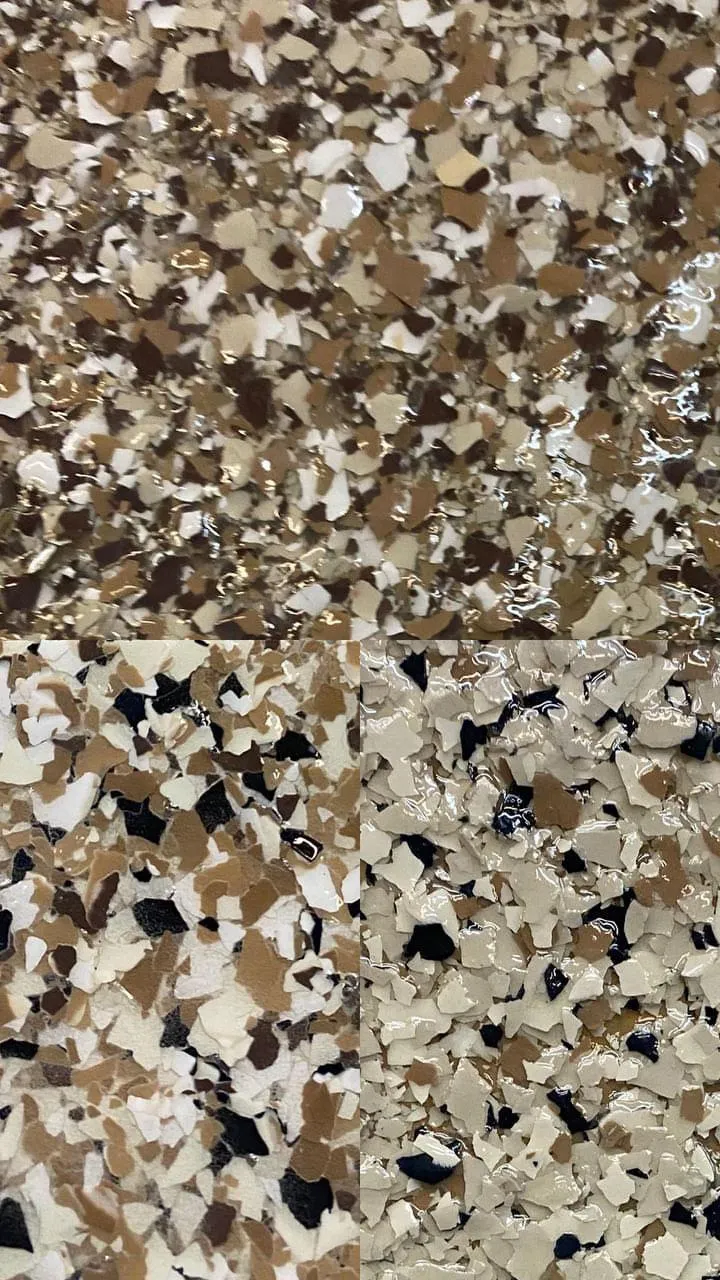

5. Customizable Aesthetics

Why settle for plain when you can create a look that’s uniquely yours? Polyaspartic coatings offer endless customization options—from high-gloss colors that pop to subtle, textured finishes that blend with any decor. Add flakes, tints, or quartz for a truly personalized look. Polyaspartic coatings offer both form and function, transforming floors into beautiful, high-performing surfaces that complement any space.

These benefits make polyaspartic coatings an exceptional choice for those looking to invest in a high-quality, long-lasting, and visually impressive floor. This isn’t just a surface layer; it’s a comprehensive solution that combines the best of speed, durability, and design.

Real-World Applications of Polyaspartic Coatings

Polyaspartic coatings are built for the real world, where floors need to do more than just look good. Here’s how our coatings are transforming spaces across various environments, from rugged industrial zones to stylish outdoor patios.

1. Automotive Garages and Workshops

Oil spills, grease stains, and the constant movement of heavy equipment—automotive spaces are tough on floors. Polyaspartic coatings provide the resilience these environments demand. Their high resistance to chemicals and abrasions makes them perfect for garages and workshops, standing up to everything from tire marks to dropped tools. The result? A floor that remains spotless, professional, and highly durable, even under the most challenging conditions.

2. Retail and Commercial Spaces

In retail and commercial settings, the floor needs to work as hard as the business itself. Polyaspartic coatings deliver a sleek, seamless finish that withstands heavy foot traffic while adding a touch of elegance. These floors not only improve the aesthetic but also enhance the shopping experience, offering a clean, polished look that’s easy to maintain. For busy spaces, polyaspartic coatings bring both durability and sophistication, supporting a professional atmosphere.

3. Residential Garages and Basements

For homeowners, polyaspartic coatings bring a blend of style and function to garages and basements. They offer moisture protection, UV stability, and a durable surface that stands up to everyday wear. Whether you’re storing vehicles, creating a home gym, or simply using the basement for extra living space, polyaspartic coatings ensure that your floors look fresh and last longer. It’s a practical upgrade that combines protection with visual appeal, making these spaces more versatile and inviting.

4. Outdoor Patios and Walkways

Outdoor spaces require coatings that can handle the elements, and polyaspartic coatings rise to the occasion. Resistant to weather, UV exposure, and temperature fluctuations, they maintain their color and finish, even in direct sunlight or extreme weather. Adding polyaspartic to patios and walkways not only elevates the look but also ensures that outdoor areas remain safe and beautiful year-round. Think of it as a luxurious, durable upgrade for your outdoor living spaces.

Polyaspartic vs. Epoxy Coatings

Choosing between polyaspartic and epoxy coatings can make a significant difference depending on the specific needs of the space. While both are durable and provide protection, they shine in different areas. Here’s a side-by-side look at what each offers, helping you make an informed decision:

1. Curing Speed

When time is tight, polyaspartic is the go-to choice. Its rapid curing process means floors can be ready for use within hours. Epoxy, on the other hand, requires days to cure fully, making it less ideal for projects with tight timelines. Polyaspartic’s speed is especially advantageous for commercial spaces or high-traffic areas where downtime is costly.

2. UV Stability

For areas exposed to sunlight, polyaspartic takes the lead. It’s UV stable, meaning it won’t yellow or fade when exposed to natural light. Epoxy, however, is best reserved for shaded or indoor areas, as it can discolor over time when exposed to UV rays. This makes polyaspartic a smart choice for outdoor patios, driveways, or any bright, sunlit room.

3. Durability and Chemical Resistance

Both coatings are tough, but polyaspartic offers a slight edge in abrasion and chemical resistance. This makes it a top pick for garages, workshops, and industrial floors that deal with chemicals, oils, and heavy impact. While epoxy is also highly durable, polyaspartic’s additional resilience ensures that floors remain pristine, even in harsher environments.

4. Temperature Tolerance

Polyaspartic coatings perform well across a range of temperatures, making them versatile enough for extreme climates. Whether it’s the freezing cold of a storage facility or the scorching sun on an outdoor deck, polyaspartic holds up. Epoxy, while durable, is generally less flexible with temperature extremes, making polyaspartic a more reliable choice for applications where temperature can fluctuate significantly.

5. Cost

Although polyaspartic coatings come with a higher initial price tag, they can provide greater value over time. Their long-lasting durability and minimal maintenance needs make them a cost-effective solution in the long run. Epoxy may be more budget-friendly upfront, but polyaspartic’s low maintenance requirements and extended lifespan often make it the better investment.

Conclusion: Deciding between polyaspartic and epoxy comes down to the specific demands of your space. If you need a quick turnaround, UV stability, and top-tier durability, polyaspartic stands out. For budget-conscious indoor projects, epoxy remains a strong contender. Both options provide excellent protection and longevity—it’s simply a matter of choosing the right tool for the job.

Installation Process for Polyaspartic Coatings

Installing polyaspartic coatings is a precise, technical process that requires careful timing and skilled application. With a curing time as fast as 1-4 hours, every step counts. Here’s a breakdown of the installation stages that ensure a flawless, durable finish:

1. Surface Preparation

The foundation of any high-quality polyaspartic coating lies in meticulous surface preparation. The surface must be clean, smooth, and free of imperfections. Any debris, dust, or cracks can compromise adhesion, so professional installers often use grinding or shot blasting to achieve a perfectly prepped surface. This step ensures the coating bonds tightly, setting the stage for a long-lasting finish.

2. Primer Application

Next comes the primer. Applying a primer layer may seem like a small step, but it’s essential for the coating’s longevity. The primer strengthens the bond between the polyaspartic coating and the substrate, enhancing durability and adhesion. Skipping this step risks peeling or bubbling, especially in high-traffic areas, so a quality primer application is non-negotiable.

3. Coating Application

Once the primer is ready, the polyaspartic coating itself is applied. This step requires precision and speed; the polyaspartic mixture cures quickly, allowing limited time for adjustments. Installers must work efficiently to spread the coating evenly, adding any textures or design elements immediately. This step showcases the expertise of the installer, as a smooth, consistent application is key to a professional finish.

4. Curing Time

Polyaspartic coatings truly shine with their fast curing times. Depending on the environmental conditions, they cure within 1 to 4 hours. This rapid curing minimizes downtime, making polyaspartic ideal for spaces that need a quick turnaround. Once cured, the floor is ready to withstand traffic and the elements.

5. Final Inspection

Quality control is critical. After curing, a final inspection ensures that the coating has bonded perfectly, with even coverage and no visible imperfections. This final check guarantees that the floor meets high standards of durability and appearance, ready to impress and perform.

Each stage of the installation process is vital, from surface prep to final inspection. With polyaspartic coatings, attention to detail during installation translates into years of resilience and style. This isn’t just about covering a floor—it’s about creating a surface that’s built to last.

Maintenance and Longevity

Polyaspartic coatings are built to last—up to two decades or more with the right care. Maintaining their durability and sleek appearance is straightforward, but a few simple habits can make a big difference in keeping them looking fresh and flawless over the years. Here’s how to get the most life out of your polyaspartic-coated floor:

1. Regular Cleaning

A quick sweep or mop goes a long way. Routine cleaning removes dirt and debris that could scratch the surface over time. Simple upkeep like this keeps the coating clear and vibrant, preserving its polished look and making more intensive maintenance unnecessary. Think of it as a quick and easy way to keep the floor looking brand new.

2. Avoid Harsh Chemicals

While polyaspartic coatings are highly resistant to chemicals, it’s best to stick with pH-neutral cleaners. Harsh chemicals can wear down the finish over time, so choosing mild, gentle cleaners will help the coating maintain its integrity. This simple switch extends the floor’s lifespan and keeps it looking sharp.

3. Prompt Spill Cleanup

For areas prone to spills—garages, workshops, or kitchens—a prompt cleanup is key. Polyaspartic coatings are designed to resist stains and chemicals, but wiping up spills right away prevents any potential long-term damage. This habit is especially useful in high-use spaces where messes are frequent.

4. Avoid Sharp Objects

While these coatings are highly durable, heavy or sharp items can still cause scratches if they come into direct contact with the surface. Use caution with heavy tools or furniture, and consider adding protective pads under items that may shift. This simple precaution protects the floor from accidental scrapes, ensuring it stays pristine for years.

With a little routine care, polyaspartic-coated floors can retain their stunning look and impressive durability. These maintenance habits aren’t just about keeping things clean—they’re about preserving an investment that combines functionality and beauty. By following these easy steps, you’ll keep your floor in top condition, ready to impress year after year.

Frequently Asked Questions (FAQs)

What are polyaspartic coatings made of?

Polyaspartic coatings are formulated from aliphatic polyurea, a compound specifically designed to provide rapid curing and exceptional durability. This unique chemistry gives polyaspartics their superior strength and resilience.

How long do polyaspartic coatings last?

With routine maintenance, polyaspartic coatings can last 15-20 years or even longer. Their longevity makes them a worthwhile investment for both residential and commercial spaces.

Can polyaspartic coatings be used outdoors?

Absolutely. Thanks to their UV resistance, polyaspartic coatings are ideal for outdoor settings like patios, walkways, and driveways. They maintain their color and integrity even under direct sunlight.

Are polyaspartic coatings environmentally friendly?

Yes, many polyaspartic products are low in volatile organic compounds (VOCs), making them an eco-friendly choice. They provide a durable, high-performance surface with minimal environmental impact.

Conclusion

Polyaspartic coatings bring together the best of speed, strength, and style, offering a transformative solution for both residential and commercial spaces. As a long-term investment, they pay off in durability and visual appeal, standing up to daily use and environmental exposure without compromise.

For those ready to elevate their floors, polyaspartic coatings represent the fusion of luxury and practicality. At Onyx Luxury Epoxy, we bring this balance to every project, ensuring each floor is as resilient as it is beautiful. Consider polyaspartic coatings for your next upgrade—a choice that’s both visually stunning and built to endure.

Author Bio

Drake McMillen is a seasoned flooring expert and co-founder of Onyx Luxury Epoxy, with years of experience in transforming residential and commercial spaces through advanced coating solutions. With a keen eye for both materials and application techniques, Drake is dedicated to delivering floors that offer durability, beauty, and longevity. His hands-on approach and commitment to quality make every project a showcase of craftsmanship and functionality.

References and Citations