The Ultimate Guide to Epoxy Garage Floor Coatings in Lenexa, Kansas

Transform your garage floor into a stunning, durable masterpiece with Onyx Luxury Epoxy. Epoxy garage floor coatings are the ultimate solution for homeowners and business owners in Lenexa, Kansas. Known for their unparalleled strength, aesthetic appeal, and protective qualities, these coatings turn ordinary concrete into stylish, resilient surfaces. Dive into our comprehensive guide to discover the benefits, application process, types, maintenance tips, and how to choose the best epoxy garage floor coating tailored to your needs in Lenexa.

What is Epoxy?

Epoxy is a high-performance polymer formed by mixing epoxide resin and polyamine hardener. This combination creates a robust, durable, and chemically resistant material that bonds strongly with concrete surfaces. When used as a floor coating, epoxy offers a range of benefits, making it an ideal choice for garage floors.

Benefits of Epoxy Garage Floor Coatings

Durability and Strength: Epoxy coatings are designed to endure heavy traffic, making them perfect for garages that house vehicles and heavy equipment. Their robust nature ensures long-lasting performance even under the toughest conditions.

Chemical Resistance: Epoxy floors are highly resistant to oil, gasoline, and cleaning agents, making them ideal for spaces prone to spills. This resistance helps maintain a pristine appearance and functionality despite exposure to harsh substances.

Aesthetic Appeal: Available in a variety of colors and finishes, including metallic and flake systems, epoxy can significantly enhance the look of your garage. Custom color blending allows for a personalized touch, transforming your garage into a stylish and functional space.

Easy Maintenance: The smooth, non-porous surface of epoxy floors makes them exceptionally easy to clean and maintain. Spills are simple to wipe away, ensuring your garage remains tidy with minimal effort.

Enhanced Safety: Epoxy coatings can be formulated with non-slip additives, providing a safer surface, especially in areas with frequent spills and moisture. This added traction helps prevent accidents, ensuring a secure environment.

Protective Qualities: By sealing the concrete surface, epoxy coatings protect against moisture, stains, and cracks, thereby extending the lifespan of your garage floor. This protective barrier ensures your floor remains in top condition for years to come.

Types of Epoxy Garage Floor Coatings

Water-Based Epoxy: This type is user-friendly and easy to apply, making it suitable for DIY projects. While it offers a durable finish, it may not be as robust as other types of epoxy coatings.

Solvent-Based Epoxy: Known for its strong adhesion and enhanced durability, solvent-based epoxy is more resistant to chemicals. However, it comes with a stronger odor and higher VOC content, requiring proper ventilation during application.

100% Solid Epoxy: The most durable option available, 100% solid epoxy contains no solvents, resulting in a thicker and more resilient coating. This makes it ideal for commercial settings and premium residential use where maximum durability is desired.

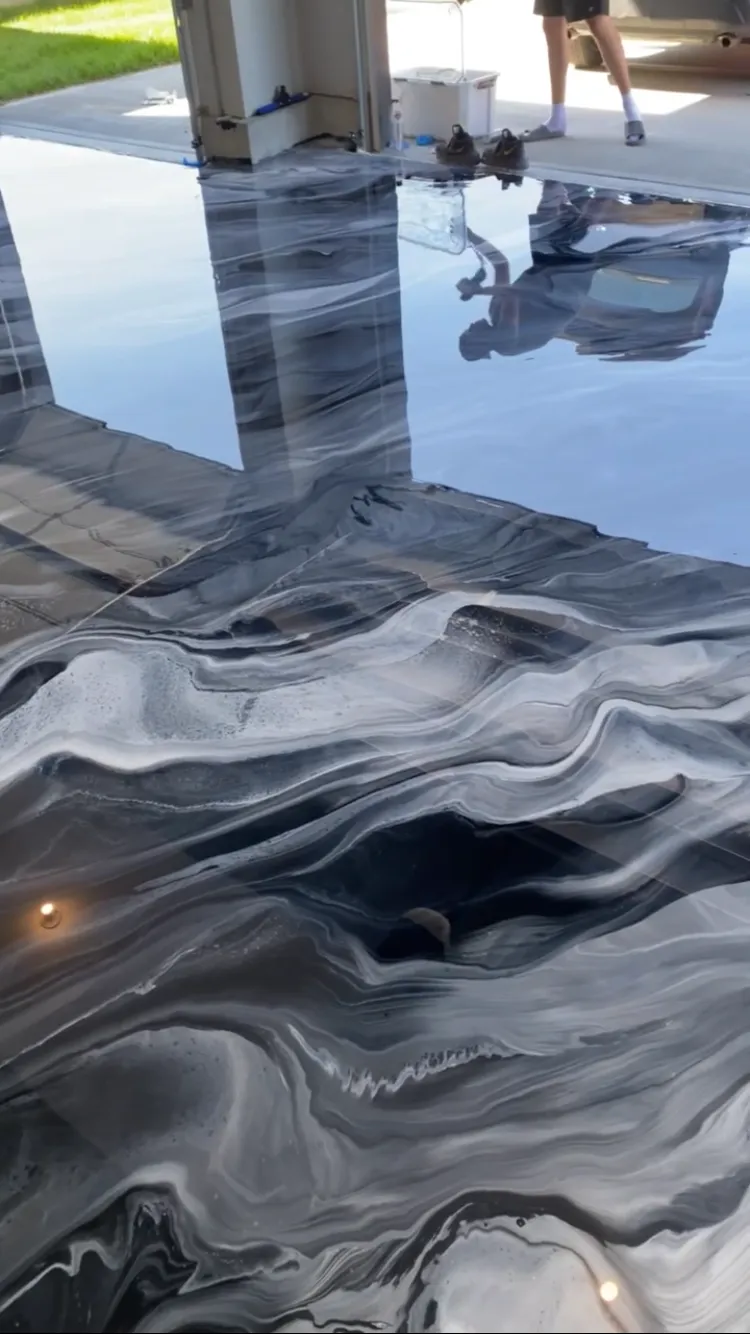

Metallic Epoxy: This type contains metallic pigments, creating a shiny, reflective surface with a unique three-dimensional appearance. It's perfect for making a bold design statement in your garage.

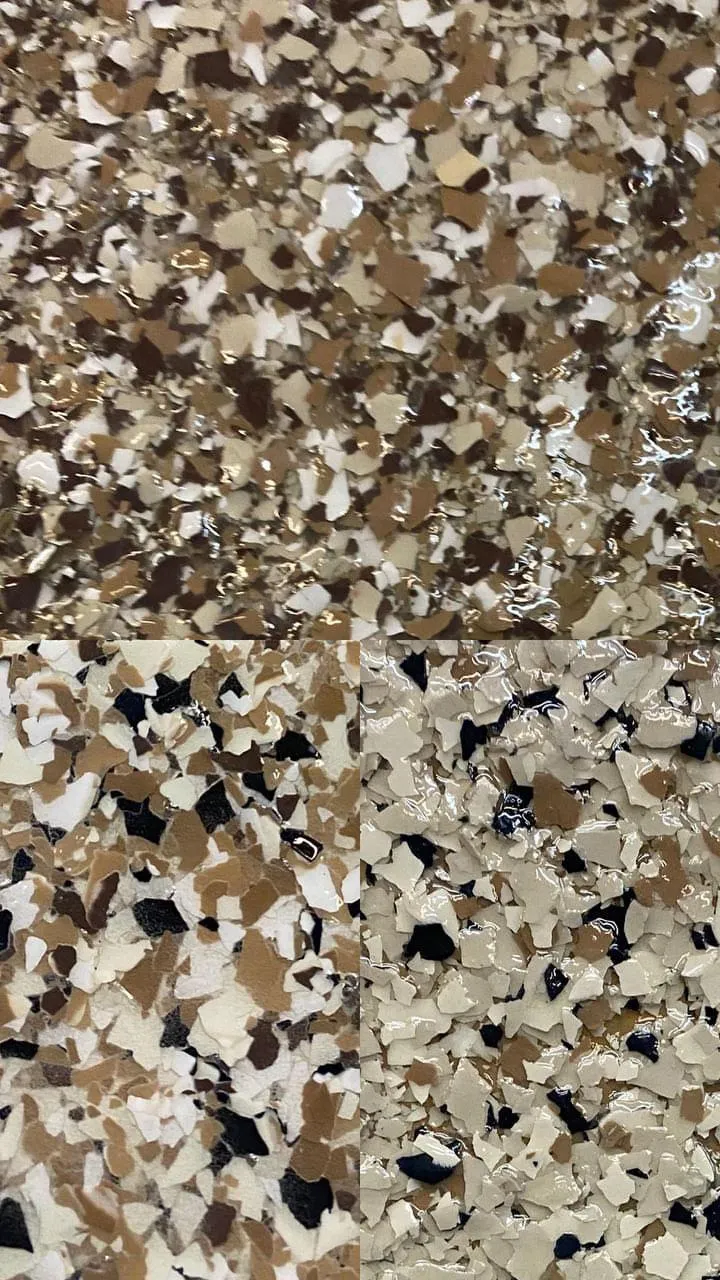

Flake Epoxy: Decorative flakes are added to the epoxy, providing a textured finish that is both visually appealing and slip-resistant. This type of epoxy not only enhances the look of your garage but also improves safety.

Preparing Your Lenexa Garage Floor for Epoxy Coating

Proper preparation is crucial for a successful epoxy application. Follow these steps to ensure the best results:

Clean the Surface: Begin by removing all items from the garage and thoroughly cleaning the concrete floor. Use a degreaser to tackle oil or grease stains, ensuring the surface is completely free of dirt and contaminants.

Repair Cracks and Imperfections: Inspect the floor for any damage. Use a concrete patching compound to repair cracks and imperfections, creating a smooth, even surface for the epoxy application.

Etch the Concrete: Etching the concrete improves epoxy adhesion. Use an etching solution or muriatic acid to prepare the surface, then rinse thoroughly and allow the floor to dry completely.

Moisture Test: Conduct a moisture test by taping a plastic sheet to the floor. If moisture collects under the sheet, address the issue before applying the epoxy to prevent adhesion problems.

Priming: Apply a primer to the clean, dry floor to enhance adhesion and durability of the epoxy coating. Allow the primer to dry completely before moving on to the epoxy application.

Applying Epoxy Garage Floor Coating in Lenexa

Mixing the Epoxy: Carefully follow the manufacturer’s instructions for mixing the resin and hardener. Proper mixing is essential for the epoxy to cure correctly.

Application: Start by cutting in the edges of the floor with a brush. Then, use a roller to apply the first coat of epoxy evenly across the main areas. Ensure a consistent and thorough application for the best results.

Adding Decorative Flakes (Optional): If you want a textured finish, sprinkle decorative flakes onto the wet epoxy. This step adds visual interest and slip resistance to your floor.

Second Coat: Once the first coat has cured, apply a second coat of epoxy. This layer adds durability and ensures a smooth, uniform finish.

Topcoat (Optional): For extra protection and a glossy finish, apply a clear topcoat over the cured epoxy. This additional layer enhances the longevity and appearance of your garage floor.

Curing and Final Steps

Allow the epoxy to cure according to the manufacturer’s guidelines. Avoid walking on the floor until fully cured, and wait at least a week before driving on it.

Maintaining Your Epoxy Garage Floor in Lenexa

Regular Cleaning: To keep your epoxy garage floor looking its best, sweep or vacuum regularly to remove dirt and debris. Mop the floor with a mild detergent solution to maintain its shine and cleanliness. This routine maintenance helps prevent dust and grime from accumulating and keeps your floor in top condition.

Avoid Abrasive Cleaners: Use non-abrasive cleaning tools and products to avoid scratching or damaging the epoxy surface. Soft bristle brushes, microfiber mops, and gentle cleaning agents are ideal for preserving the integrity of your floor.

Protective Mats: Place protective mats in high-traffic areas or under vehicles to reduce wear and tear on your epoxy floor. Mats can catch dirt, oil, and other substances, preventing them from coming into direct contact with the epoxy and extending its lifespan.

Address Spills Promptly: Clean up spills immediately to prevent staining and potential damage to the epoxy coating. Prompt attention to spills, especially those involving chemicals or oils, will help maintain the floor's appearance and durability.

Periodic Inspections: Regularly inspect your epoxy garage floor for signs of wear or damage. Address any issues promptly to prevent them from worsening. Early detection and repair of cracks, chips, or areas of wear will ensure your floor remains in excellent condition.

Comparing Epoxy to Other Garage Floor Coatings

Polyurethane: Polyurethane coatings offer excellent durability and UV resistance, making them a great choice for garage floors exposed to sunlight. However, they are more expensive than epoxy and often require professional installation due to their complex application process.

Acrylic Sealer: Acrylic sealers are easy to apply and provide a cost-effective option for garage floor protection. However, they are less durable than epoxy coatings and typically require frequent reapplication to maintain their protective qualities.

Polyaspartic Coating: Polyaspartic coatings cure quickly, making them an efficient choice for garage floors. They are extremely durable and resistant to various environmental factors. However, this high performance comes at a higher cost, making polyaspartic coatings a more expensive option.

Concrete Stain: Concrete stains add color to your garage floor, offering an aesthetic upgrade. However, they provide less protection compared to epoxy coatings. While concrete stains can enhance the appearance of your floor, they do not offer the same level of durability and resistance to wear and tear.

Common Issues and Solutions

Peeling: One of the most common issues with epoxy coatings is peeling, which usually occurs due to inadequate surface preparation or the presence of moisture. To prevent peeling, ensure thorough preparation of the concrete surface, including cleaning, etching, and repairing any cracks. Additionally, perform a moisture test before applying the epoxy to ensure the surface is dry.

Bubbling: Bubbling can occur if epoxy is applied too thickly or if air bubbles are not properly removed. To avoid this issue, apply the epoxy in thin, even layers and use a roller to remove any air bubbles. Ensuring a smooth, bubble-free application will result in a more durable and attractive finish.

Discoloration: Exposure to UV light can cause epoxy to discolor over time. To maintain the appearance of your floor, use UV-resistant epoxy or apply a UV-protective topcoat. These products help preserve the color and appearance of the epoxy, even in areas exposed to sunlight.

Slippery Surface: Epoxy floors can become slippery, especially when wet. To enhance safety, add non-slip additives to the epoxy mixture or use a textured flake system. These solutions provide extra traction, reducing the risk of slips and falls.

Environmental and Health Considerations

VOC Emissions: Volatile Organic Compounds (VOCs) emitted by some epoxy products can impact indoor air quality and health. Opt for low-VOC or VOC-free epoxy products to minimize these emissions and create a safer environment.

Proper Ventilation: Ensure good ventilation during the application process to dissipate any fumes and maintain air quality. Open windows and use fans to increase airflow and reduce the concentration of any potentially harmful vapors.

Protective Gear: When applying epoxy, it's essential to wear protective clothing, gloves, and a respirator. This gear helps protect your skin from contact with the epoxy and prevents inhalation of any fumes, ensuring a safe application process.

Choosing the Right Epoxy Coating

Intended Use: Assess the level of traffic and the frequency of spills in your garage. High-traffic areas or spaces prone to chemical spills may require more durable epoxy coatings designed to withstand these conditions.

Aesthetic Preferences: Select finishes that align with your personal style and the overall design of your home. With options ranging from sleek metallics to practical flake systems, you can find an epoxy coating that enhances the look of your garage.

Budget: While higher-quality epoxy products might come with a higher upfront cost, they often offer better long-term value due to their enhanced durability and longevity. Consider your budget but also weigh the benefits of investing in premium products.

Professional vs. DIY: Determine whether you want to undertake the project yourself or hire professionals. Professional installation can ensure a flawless finish and save you time and effort, while DIY options might be more cost-effective but require significant preparation and skill.

Epoxy Flooring Trends in Lenexa

Metallic Finishes: These luxurious, high-gloss finishes create a unique and eye-catching look for your garage. Metallic epoxy coatings add depth and a reflective quality that can make your floor stand out.

Flake Systems: Practical and stylish, flake systems incorporate decorative flakes into the epoxy, providing a textured finish that is both visually appealing and slip-resistant. This trend is perfect for those looking to combine safety with aesthetic appeal.

Custom Colors: Personalized color blends allow homeowners to match their epoxy flooring with the existing design elements of their home. Custom colors provide a tailored look that enhances the overall cohesiveness of your property.

Eco-Friendly Options: Sustainable epoxy products with low VOCs are becoming increasingly popular. These eco-friendly options are designed to reduce environmental impact while still providing the durability and aesthetic appeal you expect from epoxy flooring.

Conclusion

Epoxy garage floor coatings from Onyx Luxury Epoxy blend durability, aesthetic appeal, and protective qualities, making them the premier choice for garages in Lenexa, Kansas. Understanding the benefits, types, application process, and maintenance will help you make an informed decision, ensuring a long-lasting, beautiful garage floor.