Lifespan and Long-Lasting Protection of Epoxy Garage Floors

Epoxy garage floors are renowned for their durability and long-lasting protection, making them a popular choice among homeowners. This comprehensive guide will explore the lifespan of epoxy garage floors, the factors that contribute to their longevity, and how they provide enduring protection for your garage. Whether you're considering epoxy for your garage or looking to maintain an existing epoxy floor, this article will provide valuable insights.

What Is Epoxy Flooring?

Epoxy flooring is a type of surface coating made from a combination of resin and hardener. When these two components are mixed, they form a rigid plastic material that bonds exceptionally well to concrete surfaces. This creates a durable and resilient coating that can withstand heavy use and harsh conditions, making it ideal for garage floors.

Types of Epoxy Coatings

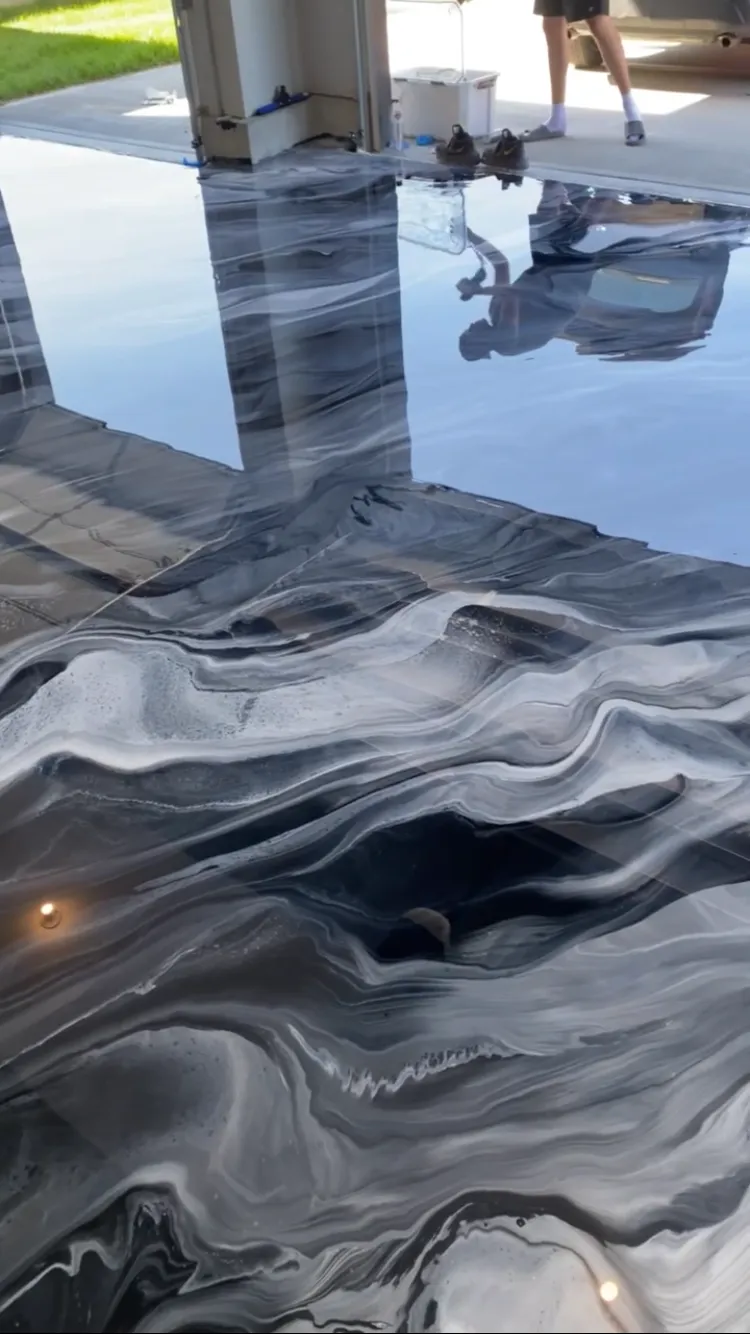

Metallic Epoxy Coatings: These coatings contain metallic pigments that create a shimmering, reflective surface. They are ideal for those looking to make a bold statement with their garage floor.

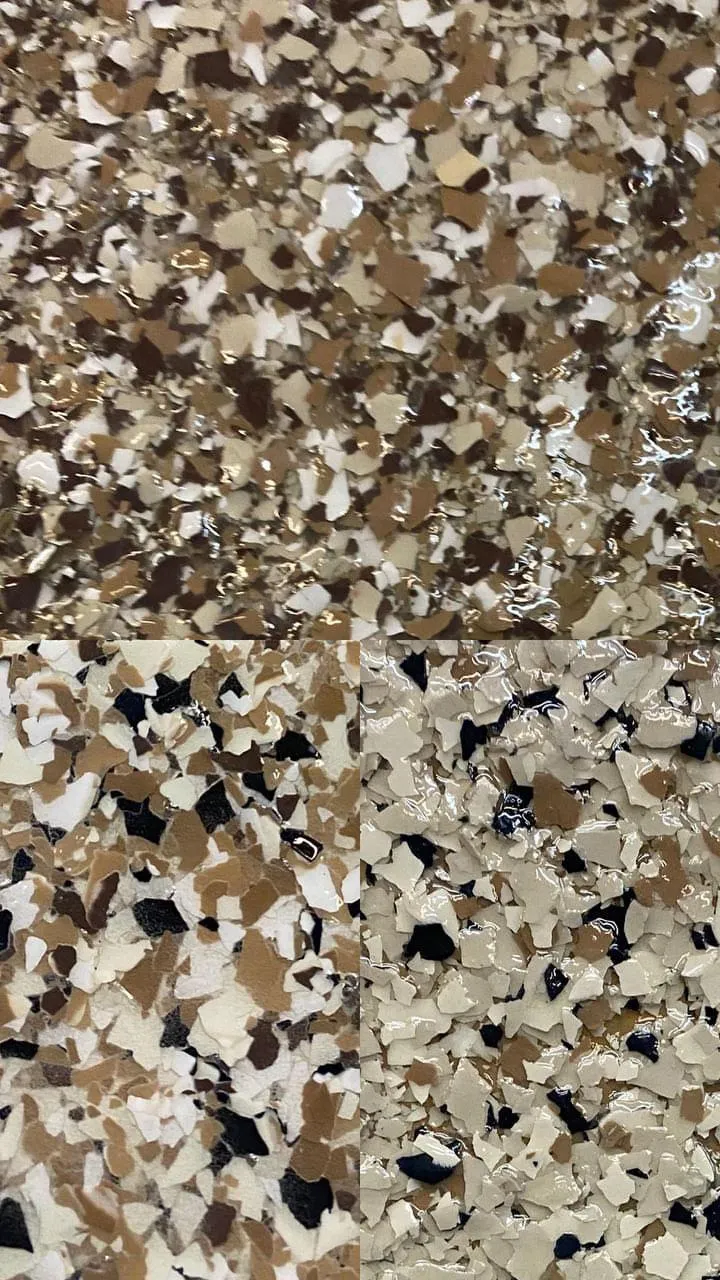

Flake Epoxy Coatings: These include colored flakes scattered over the epoxy base, creating a textured, multi-colored finish. This type is excellent for hiding imperfections and adding a decorative touch.

Solid Color Epoxy Coatings: These provide a uniform, solid color finish. They are perfect for those who prefer a clean, minimalist look.

Composition of Epoxy Coatings

Epoxy coatings are composed of two primary components: resin and hardener. The resin is typically a clear or lightly colored liquid, while the hardener is a catalyst that initiates the curing process. When mixed, these components undergo a chemical reaction that forms a hard, plastic-like material. This reaction is exothermic, meaning it releases heat, which helps the epoxy cure and bond to the concrete surface.

Lifespan of Epoxy Garage Floors

Average Lifespan

The average lifespan of an epoxy garage floor ranges from 5 to 20 years, depending on various factors such as the quality of the epoxy, the level of traffic, and how well the floor is maintained. High-quality epoxy coatings, like those offered by Onyx Luxury Epoxy, come with a lifetime warranty, ensuring long-lasting durability.

Case Study: Longevity in Action

A study conducted by the National Association of Home Builders found that epoxy-coated garage floors can last up to 20 years with proper maintenance. This longevity is attributed to the coating's resistance to abrasion, impact, and chemicals. Homeowners who invest in epoxy coatings can expect their garage floors to remain in excellent condition for many years.

Factors Affecting Lifespan

Quality of Epoxy: High-quality epoxy coatings are formulated to withstand heavy use and harsh conditions, contributing to a longer lifespan.

Surface Preparation: Proper surface preparation is crucial for the success of an epoxy coating. A well-prepared surface ensures good adhesion and durability.

Application Process: The application process, including mixing, applying, and curing the epoxy, plays a significant role in the coating's longevity.

Maintenance: Regular maintenance, such as cleaning and inspecting the floor, can extend the lifespan of an epoxy coating.

Comparison with Other Flooring Options

Epoxy flooring offers a longer lifespan compared to other flooring options such as concrete sealers, paint, and tiles. Concrete sealers and paint may need to be reapplied every few years, while tiles can crack and require replacement. In contrast, epoxy coatings provide a durable and long-lasting solution that requires minimal maintenance.

Long-Lasting Protection of Epoxy Garage Floors

Durability and Resistance

Epoxy coatings are highly resistant to wear and tear, making them ideal for high-traffic areas like garages. They can withstand heavy machinery, vehicles, and even chemical spills without deteriorating.

Chemical Resistance

Epoxy coatings are resistant to a wide range of chemicals, including oil, gasoline, and cleaning agents. This resistance protects the underlying concrete from chemical damage and staining. In industrial settings, epoxy coatings are often used to protect floors from harsh chemicals and heavy machinery.

Protection Against Moisture

Concrete is porous and can absorb moisture, leading to issues such as mold, mildew, and structural damage. Epoxy coatings create a non-porous barrier that prevents moisture from penetrating the concrete. This protection is particularly important in garages, where water from vehicles and outdoor elements can pose a risk.

Moisture Barrier

Epoxy coatings provide an effective moisture barrier, preventing water from seeping into the concrete. This barrier helps protect the concrete from damage caused by freeze-thaw cycles, which can lead to cracks and deterioration. Additionally, the moisture barrier reduces the risk of mold and mildew growth, promoting a healthier garage environment.

Impact and Abrasion Resistance

Epoxy coatings are designed to withstand heavy impacts and abrasion, making them suitable for garages where tools, equipment, and vehicles are frequently used. The coating's hardness and resilience protect the concrete from damage caused by dropped objects, heavy loads, and constant foot traffic.

Case Study: Impact Resistance

In a study conducted by the American Society for Testing and Materials (ASTM), epoxy coatings demonstrated superior impact resistance compared to other flooring options. The study found that epoxy coatings could withstand impacts from heavy objects without cracking or chipping, making them an ideal choice for garage floors.

UV Resistance

Some epoxy coatings are formulated with UV-resistant additives, protecting the floor from sun damage and fading. This UV resistance is particularly beneficial for garages with windows or open doors, where the floor is exposed to sunlight.

UV Protection

UV-resistant epoxy coatings prevent the floor from yellowing or fading due to sun exposure. This protection helps maintain the floor's appearance and extends its lifespan, ensuring that it remains attractive and functional for many years.

Scratch and Stain Resistance

Epoxy coatings are highly resistant to scratches and stains, making them easy to maintain and keep looking pristine. The non-porous surface of epoxy coatings prevents stains from penetrating the material, allowing for easy cleanup of spills and messes.

Stain Resistance

Epoxy coatings are resistant to common garage stains such as oil, grease, and tire marks. The non-porous surface prevents these substances from penetrating the coating, making it easy to wipe away spills and keep the floor looking clean.

Enhanced Safety Features

Epoxy coatings can be customized with slip-resistant additives, providing a safer surface for walking and working. The reflective properties of epoxy coatings also enhance lighting in the garage, improving visibility and reducing the risk of accidents.

Slip-Resistance

Slip-resistant additives, such as aluminum oxide or polymer grit, can be mixed into the epoxy coating to create a textured surface. This texture provides additional traction, reducing the likelihood of slips and falls. Slip-resistant epoxy coatings are particularly beneficial in garages where water, oil, or other liquids may be present.

Improved Visibility

The reflective properties of epoxy coatings can enhance the lighting in your garage. By reflecting light, the coating makes the space brighter and more inviting. Improved visibility can also make it easier to work on projects, locate tools, and navigate the garage safely.

Maintenance Tips for Extending the Lifespan of Epoxy Garage Floors

Regular Cleaning Routine

Maintaining an epoxy-coated garage floor is easy with a regular cleaning routine. Use a soft broom or mop to remove dust and debris. For deeper cleaning, use a mild detergent and water. Avoid using abrasive cleaners, as they can damage the epoxy surface.

Cleaning Tips

Regular Sweeping: Use a soft-bristle broom to remove dust and debris from the floor.

Mopping: For deeper cleaning, use a mop with a mild detergent and water. Avoid using harsh chemicals or abrasive cleaners, as they can damage the epoxy surface.

Spot Cleaning: Address spills and stains promptly to prevent them from setting in. Use a soft cloth or sponge and a gentle cleaning solution to remove any marks.

Avoiding Damage

To prevent scratches and scuffs, place mats or rugs in high-traffic areas. Be cautious when moving heavy objects, and consider using furniture pads to protect the floor. Promptly clean up any spills to prevent staining.

Preventative Measures

Use Mats and Rugs: Place mats or rugs in high-traffic areas, such as entryways and workstations, to protect the epoxy surface from scratches and scuffs.

Furniture Pads: Use furniture pads under heavy objects to prevent damage when moving them.

Avoid Dragging: Avoid dragging heavy objects across the floor, as this can cause scratches and scuffs.

Periodic Inspections

Regularly inspect your epoxy-coated floor for signs of wear and tear. Look for any chips, cracks, or areas where the coating may be peeling. Addressing these issues early can prevent more significant problems down the line. If necessary, consider re-coating the floor to maintain its appearance and durability.

Inspection Checklist

Check for Chips and Cracks: Inspect the floor for any chips, cracks, or areas where the coating may be peeling.

Assess Wear and Tear: Look for signs of wear and tear, such as fading or discoloration.

Evaluate Adhesion: Check for areas where the epoxy may be lifting or separating from the concrete.

Re-Coating and Repairs

Over time, even the most durable epoxy coatings may show signs of wear. Re-coating the floor can restore its appearance and protective properties. Small chips and cracks can be filled with epoxy fillers, while more extensive damage may require re-coating.

Re-Coating Process

Surface Preparation: The existing epoxy coating must be thoroughly cleaned and lightly sanded to ensure good adhesion for the new coat.

Mixing the Epoxy: The resin and hardener are mixed according to the manufacturer's instructions. It's essential to mix the components thoroughly to ensure a consistent and effective coating.

Applying the Epoxy: The mixed epoxy is then applied to the prepared surface using rollers or brushes. Multiple coats may be required for optimal coverage. Allow each coat to cure before applying the next.

Curing: The epoxy needs time to cure and harden. This process can take several days, depending on the type of epoxy and environmental conditions. Avoid using the garage during the curing period to ensure the coating sets properly.

Conclusion

Epoxy garage floors offer a long lifespan and provide enduring protection for your garage. With their durability, resistance to chemicals and moisture, and enhanced safety features, epoxy coatings are an excellent choice for homeowners looking to upgrade their garage floors. Proper maintenance and periodic inspections can extend the lifespan of epoxy coatings, ensuring that your garage floor remains in excellent condition for many years.

For more information on epoxy coatings and professional installation services, visit Onyx Luxury Epoxy. Explore our related blog posts for further reading:

Upgrade your garage today with Onyx Luxury Epoxy and experience the difference!